Ripper Tooth with Heavy Duty Hardox® shank for 1.0 to 1.9 tonne mini diggers

£362.14Unit price /UnavailableINC. VAT £434.57

Ripper Tooth with Heavy Duty Hardox® shank for 2.0 to 3.2 tonne mini excavators

£375.37Unit price /UnavailableINC. VAT £450.44

Ripper Tooth with Heavy Duty Hardox® shank for 3.0 to 3.9 tonne mini excavators

£410.07Unit price /UnavailableINC. VAT £492.08

Ripper Tooth with Heavy Duty Hardox® shank for 4.0 to 5.9 tonne mini excavators

£625.00Unit price /UnavailableINC. VAT £750.00

Ripper Tooth with Heavy Duty Hardox® shank for 6 to 9 tonne midi excavators

£695.00Unit price /UnavailableINC. VAT £834.00

Ripper Tooth with Heavy Duty Hardox® shank, 65mm pins for 10 to 14 tonne excavators

£1,325.00Unit price /UnavailableINC. VAT £1,590.00

Ripper Tooth with Heavy Duty Hardox® shank, 80mm pins for 18 to 24 tonne excavators

£3,375.00Unit price /UnavailableINC. VAT £4,050.00

What to Rip?

Rippers can also be used to tear up footings and floor slabs, pull up tree roots and other jobs where full machine breakout force is needed.

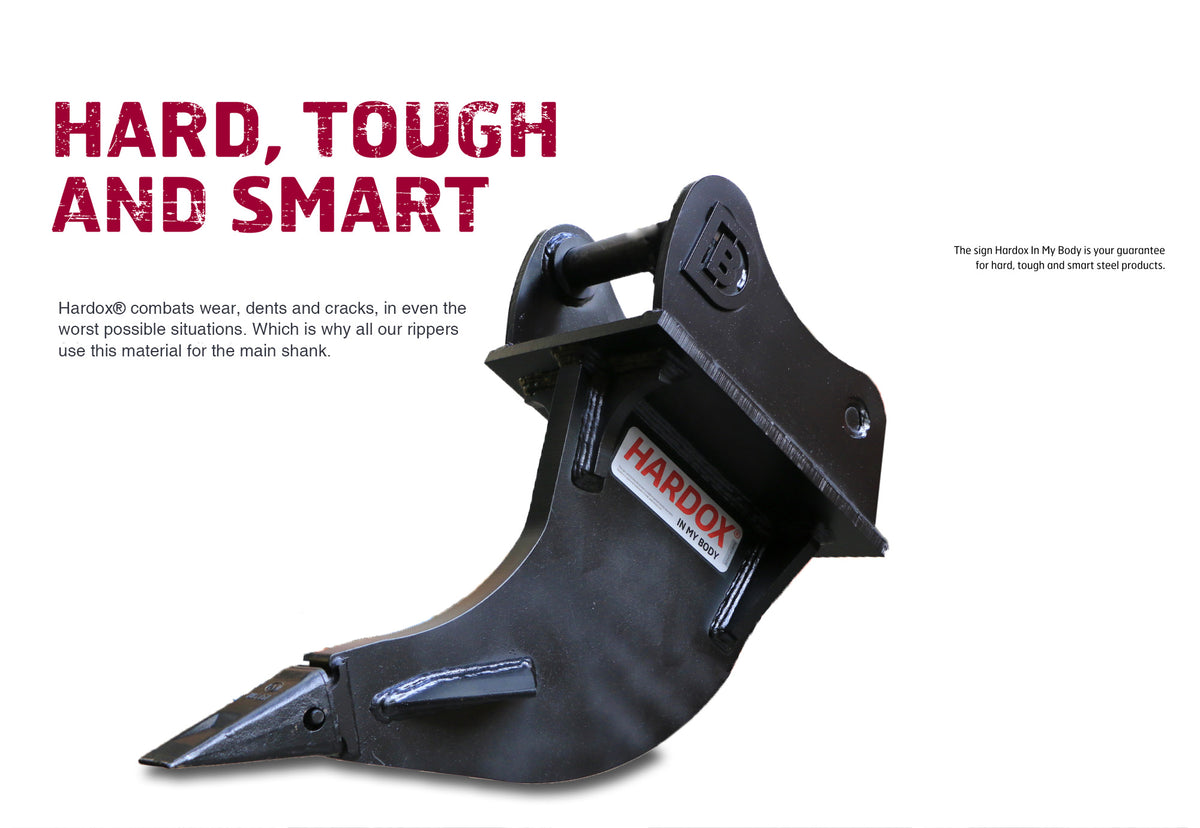

- All our ripper shanks are cut from high-wear resistance, high yield-strength Hardox® steel.

- Fitted with replaceable CAT type tip.

Our Ripper hooks are designed to take maximum excavator breakout force, in the most challenging, abrasive, compacted, rocky ground conditions.

We ensure performance and durability this by using strong, wear resistant Hardox® steel. Check out the video at the bottom of the page to see how it our performs mild steels.

All our heavy duty excavator Ripper Teeth are manufactured in our own works in Staffordshire, UK.

Official member of the Made In Britain directory.

As Seen On Site:

Heavy Duty Ripper Features:

WHY WE USE HARDOX® 450

HARDOX® shanks - accept no Substitutes

Be extremely wary of cheap lookalikes.

We make all our Ripper Shanks using Hardox® 450 steel for extra strength and wear resistance.

This gives roughly 4 times the resistance to:

- bending

- twisting

- impact and abrasion

with no extra weight penalty, compared to S275 mild steel.