Buckets - Buying & Using

There is often a degree of confusion, and even ignorance, where buckets are concerned,

and yet this is quite literally the sharp-end of the whole machine,

where all the work is done.

People spend tens, or even hundreds of thousands of pounds on the latest excavator, and then negate any advantages gained by fitting them with old, or incorrectly specified buckets. Whether they fit the same old, ‘patched-up antique’ buckets that have been knocking around their plant yard for years, or buy the cheapest new bucket they can find, irrespective of build and

quality, the net result is that their machine will under perform.

Video

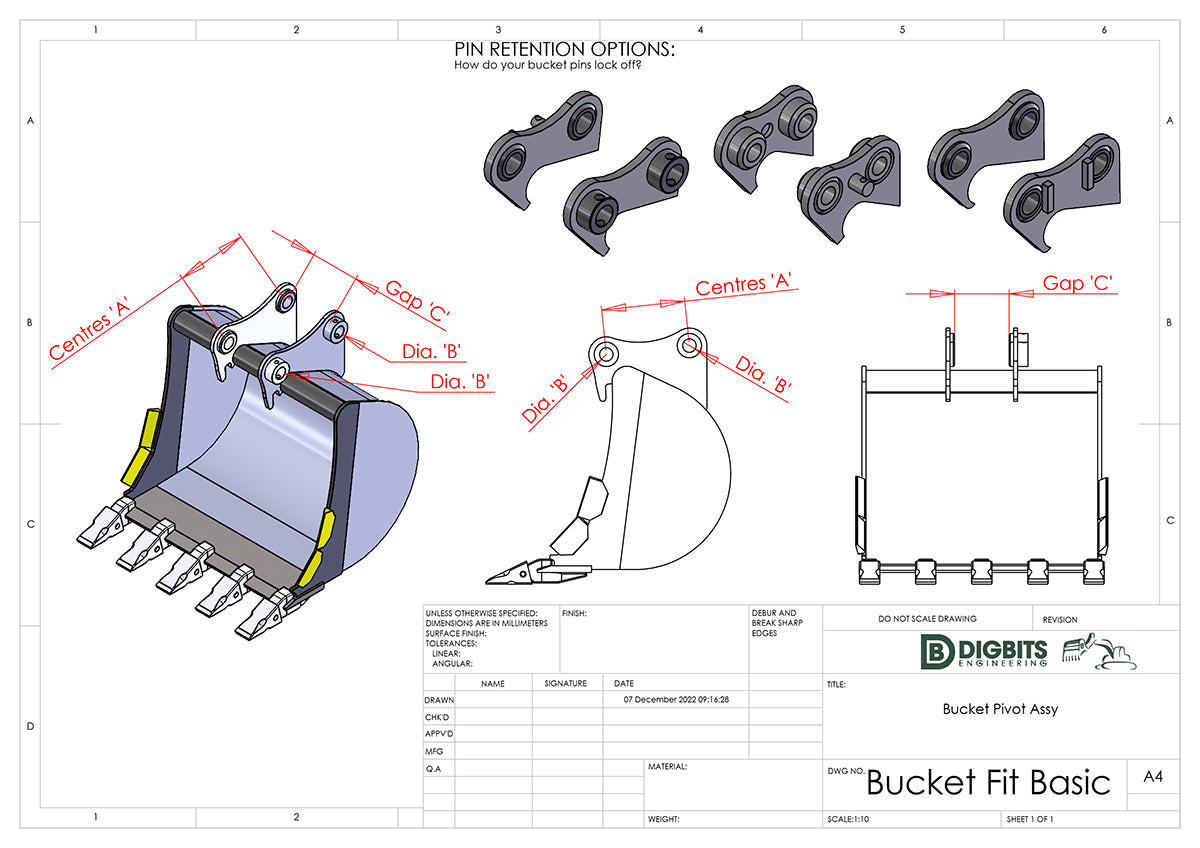

There is no 'standard' quick hitch.

Bucket fit - pivot bracket dimensions:

A potential elephant trap. Everyone thinks they have a 'standard' hitch, until they get a bucket which does not fit.

The truth is more complex; the majority of excavator quick hitches and couplers are not fitted at the OEM factory, but by the dealer or even end user.

Always double check the basic dimensions of the buckets your machine uses. Never assume they are 'standard'.

It is much cheaper for you to measure twice, than for us to weld once!

At DIGBITS, we understand that getting the right buckets, and using them

correctly is vital. Having the right tool for the job maximises

efficiency and prevents damage.

There are a few general bucket rules which apply to all excavators:

- Cycle Times:

Bear in mind that the fastest cycle times (i.e. the time taken to dig a

full bucket load, tip it into a truck/skip/hopper and return to the dig

position) are NOT necessarily achieved with the widest or largest

capacity bucket. This is especially true in harder ground conditions. - Stability:

It is not generally advisable to exceed the maximum bucket width

declared in your machines specifications. Any modifications to the

machine work equipment – boom or dipper extensions, quick-hitches etc. –

will tend to de-rate the overall machine stability. - Narrow Digging:

On most machines, the limiting factor for bucket width will be the

width of the bucket linkage and pins. It is possible to build taller

narrower buckets, though these may have a reduced breakout capability,

the potential for collisions with parts of the excavator with normal

buckets would not reach, and cannot dig deeper than the bucket itself. - Digging Buckets:

Keep the teeth in good condition, and try to catch any wear before it

becomes critical (see Repairs) to avoid expense. Do not be tempted to

use for heavy duty, demolition, rock or quarry applications – sadly most

customers who buy our XHD buckets have already scrapped a perfectly

good GP or HD buckets on these jobs. - Ditching Buckets:

These are designed for re-handling and levelling of soil, so expect

them to dig compact or rocky ground. The width of these buckets, and

their lighter construction means it is worth avoiding catching the outer

edges on objects which are firmly fixed into the ground (e.g. large

rocks or manholes) as they will bend. We are often asked why we don’t

build them heavier – the answer is that you would end up putting a

‘corskcrew’ type bend into your dipper arm! - XHD Buckets:

These can be used on any application, from digging soil to digging and

loading rocks in a quarry. Refer also to the notes on Digging Buckets

and Cycle Times. - Price. If

you’ve read the notes above, you won’t be surprised to hear that with

buckets – as with many things in life – the cheapest is rarely the best

choice. We’ve all seen the sob stories, in the papers, on the TV (on

shows like Watchdog) of people who’ve employed the cheapest builder, or

gone on the cheapest holiday, had the cheapest double-glazing fitted,

and ultimately, cheap buckets are just the same – the only good thing

about them is the price. See Specification to find out why. - Specification. Once you’ve decided the type of bucket you need – Digging, Ditching, XHD etc.

– what you really need to know is the specification, in order to make a

true comparison of what you’re getting for your money. Unfortunately,

not all bucket manufacturers are as honest and forthcoming with this

data, and for good reason too. These are the key criteria: - Manufacture Time:

We always try to sell customers the right bucket/attachment for their

job, rather than just using the ‘let’s shift what we have in stock’

approach. Often we have stock of the right kit, but equally there are

times where we need to manufacture to customers requirements. In this

case, we will tell you an accurate build date, at the time of order, and

we will stick to it. As a rough guide, we can normally guarantee the

following lead times for buckets: