How to replace worn pins and bushes on your excavator and tricks to help you fit new replacement pins and bushes.

Installing-Pins-Bushes

Boom Pins, Bushes, Seals & Shims

When components on the excavator arm are worn it becomes very difficult to dig or position attachments with accuracy. Ultimately, components failing can cause injury or death.

Digbits manufacture and stock tens of thousands of pins, bushes, shims, dust seals and linkages for machines from under one tonne up to over 45 tonnes.

Damage Prevention:

Regular inspections (as detailed by your manufacturer) and use of the grease gun are vital. Expensive damage can be caused if pins or bushes are allowed to wear to the point of failure. We frequently supply new dipper-end bosses as a result of unnecessary damage caused in this way.

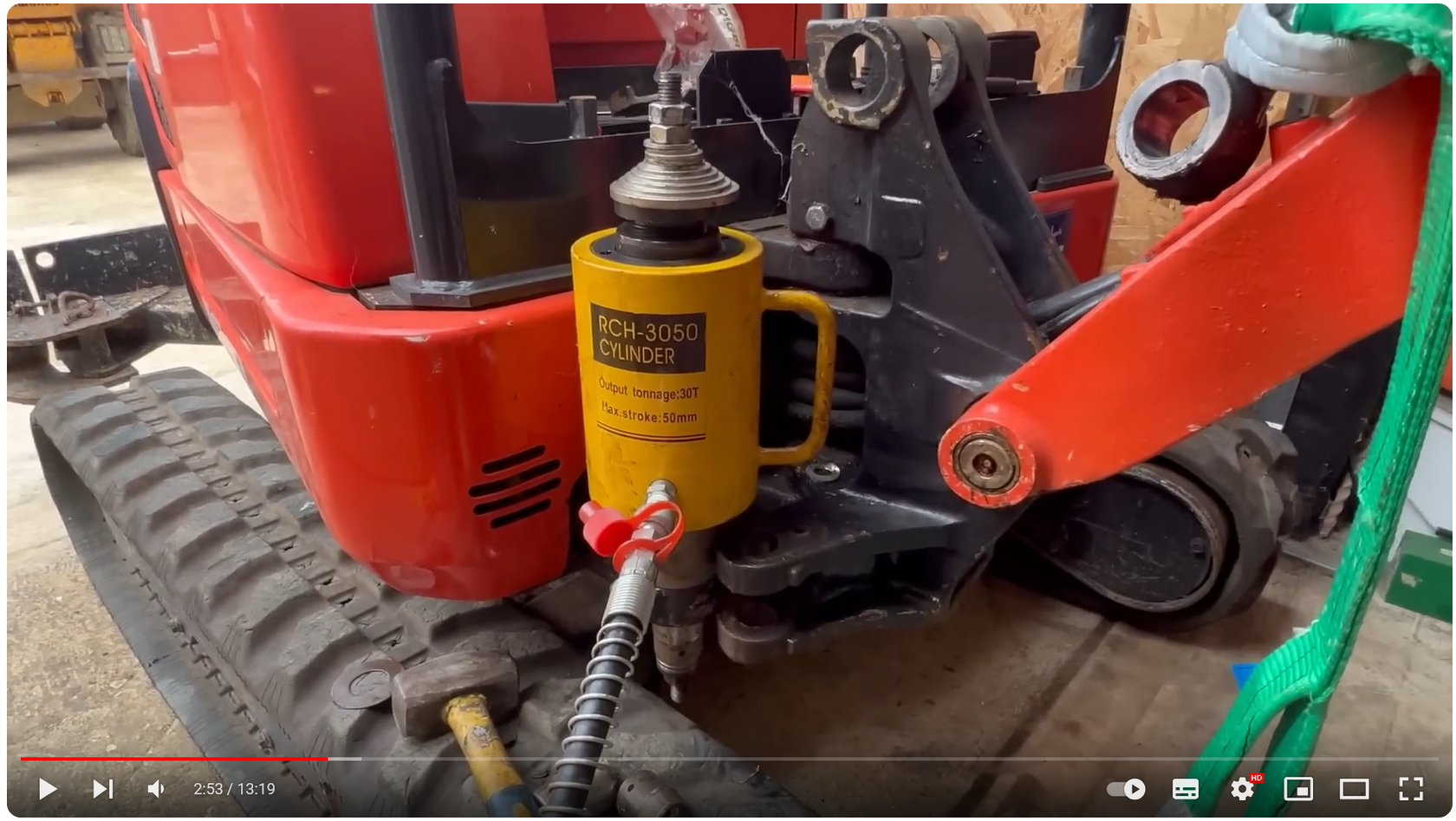

Removing Old Bushes:

Most bushes can be pushed or knocked out with a drift. If not, there are a few fitter's tricks you can use.Another way to remove old bushes is to put a ring of weld on the inside of the bush. As the weld cools the bush will contract and shrink. It can then be tapped out gently.Another method is to cut one wall of the bush, down the length of it. This will loosen its grip and make it easier to remove.

Important! Never hit hardened steel bushes directly with a steel hammer – they can shatter –, use a soft metal mallet or a wooden block, and always wear eye protection.

Important! Never use excessive force when removing or fitting hardened steel bushes into housings. In extreme cases the bush can distort the housing, causing misalignment and permanent damage, and may also shatter.

Ordering New Pins & Bushes:

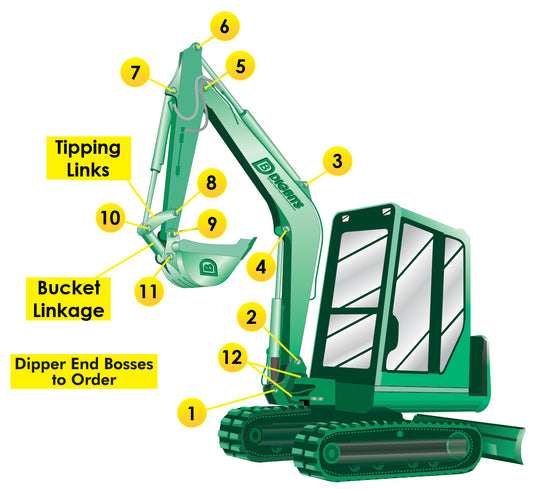

Our quick reference diagram makes it fast and easy to identify which pivot locations you need parts for.

It's best to order a kit for each location that's worn. Bushes are generally harder than pins, but over time, your machine will incur wear in both.

It's false economy to spend time and money on pins and not change bushes. Leaving bushes too long can result in them wearing through or, wearing to the point they start spinning in the housings. Either will cause damage which will require expensive line boring and re-welding.

Head over to our pins & bushes page for more information on ordering:

Fitting New Bushes:

When new machines are assembled in the factory, hardened steel bushes are often ‘shrunk fit’ or ‘freeze fit’ into housings/bosses, by dipping them into liquid nitrogen, prior to fitting. If you do not have access to these facilities, chilling the bushes in an ordinary domestic freeze (wrap them up so you don’t get oil and grease on anything edible!) will serve the same purpose.

Don’t be tempted to apply heat to the housing/boss, in an attempt to expand it, as this rarely works and often (if the walls expand inwards) makes the job even harder.

Important! Never hit hardened steel bushes directly with a steel hammer – they can shatter –, use a soft metal mallet or a wooden block, and always wear eye protection.

Important! Never use excessive force when removing or fitting hardened steel bushes into housings. In extreme cases the bush can distort the housing, causing misalignment and permanent damage, and may also shatter.