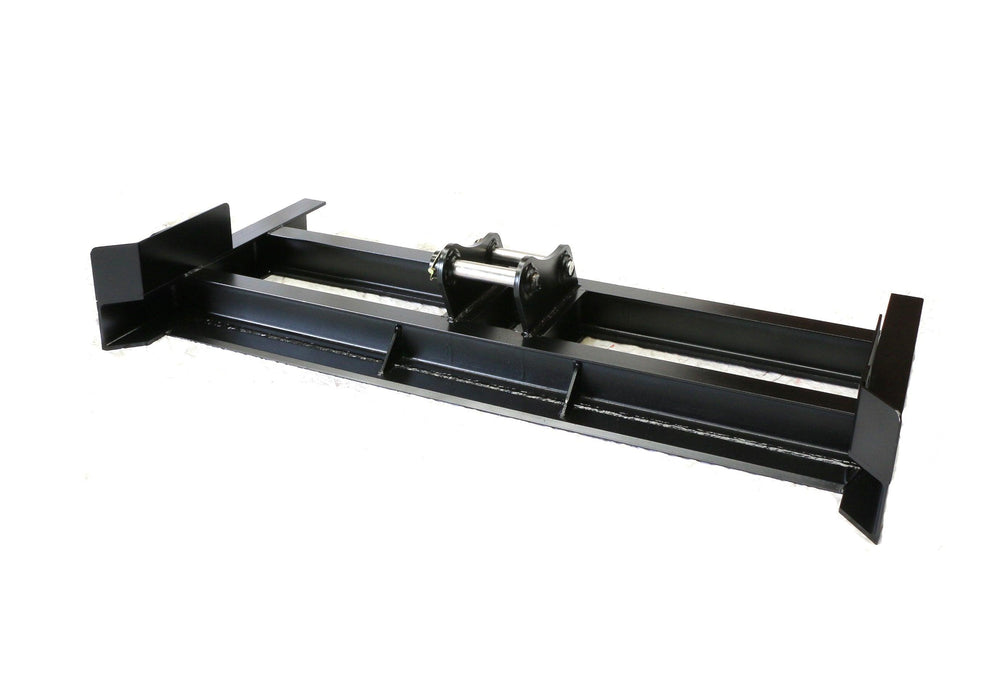

2000mm / 79" Wide Grading Beam for 4.0 to 5.9t excavators, by Digbits

INC. VAT £1,108.80

2000mm / 79" Wide Grading Beam for 4.0 to 5.9t excavators, by Digbits is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

Order before 2pm to get next day delivery for in-stock items. Shipping fees will be calculated at checkout.

Description

Description

A versatile attachment to enable precision grading and leveling on

your mini excavator. The unit is reversible and is dual purpose. Shown with optional pins. Two options can be specified at extra cost: hydraulic tilt, laser alignment guide post.

All units are built to order. Please allow 7 to 14 working days for manufacture.

To suit models including:

- Bobcat E45

- Case CX50B

- Caterpillar 304.5, 305E

- Doosan DX63, DX62R-3

- Hyundai R55-9

- JCB 8045, 8055

- Kubota KX161-3, U45, U50-3, U48-4, U55-4, 57-4

- Volvo ECR48, ECR58

- Takeuchi TB145, TB53R, TB250

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

More than just width – depth matters.

Our grading beams are designed with longer front-to-back runners for greater pitch stability and a smoother grading finish. Unlike shorter beams, they act like skis to level surfaces more effectively.

All beams are manufactured using British Steel ‘C’ and ‘I’ hot-rolled sections for strength and durability.

AS SEEN ON SITE:

What You Get

Achieve rapid, high-precision grading and leveling with your excavator, using a Grading Beam attachment. Grade wider, faster and more accurately than with an ordinary ditching or grading bucket.Available for excavators from 1.5 tonnes upwards.

All of these attachments are made to order, normally within 7-14 days.

-

Features

- The unit is double-sided, so can be used in either direction, depending on the desired finish.

- Generous, long side runners help keep the cut level.

- Quality, British Steel "C" and "I" section beams and hardened cutting edges ensure maximum straightness, rigidity and service life.

- British manufactured

-

Applications

Our Grading Beams are used on a wide variety of projects including the construction and maintenance of:

- roads and tracks

- equestrian arenas and menages

- golf courses

- caravan parks & campsites

All our excavator Grading Beams are manufactured in our own works in Staffordshire, UK.

Official member of the Made In Britain directory.

British Steel

British manufacturing is alive and well!

At our Rugeley works,in Staffordshire, we craft our excavator Grading Beam attachments using British Steel, hot-rolled beam sections produced in Scunthorpe, Lincolnshire.

From raw steel to finished product, it’s all done right here in the UK, ensuring quality, sustainability, and supporting local industry.