PEL-JOB EB22.4 TS02 200mm Tree Shear 2.0-4.9 tonne excavators

INC. VAT £3,568.80

PEL-JOB EB22.4 TS02 200mm Tree Shear 2.0-4.9 tonne excavators is backordered and will ship as soon as it is back in stock.

Delivery and Shipping

Delivery and Shipping

Order before 2pm to get next day delivery for in-stock items. Shipping fees will be calculated at checkout.

Where am I made?

Where am I made?

Description

Description

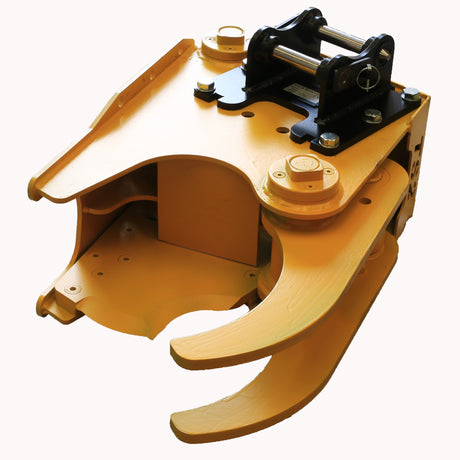

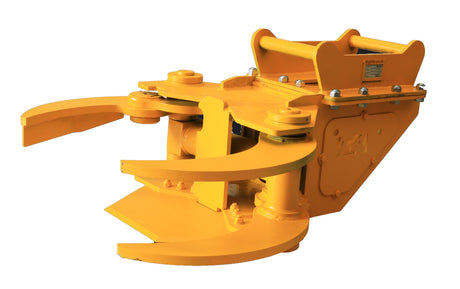

Tree Shear with 200mm cut for mini excavators from 2.0 to 4.9 tonnes. This grab style shear is designed to enable the felling of smaller trees and saplings complete and also the cutting up of wood on the ground. Ideal for thinning young forests and also maintaining or removing hedges. The unit cuts and holds the tree in a grabbing action.

The excavator mounting bracket can be bolted onto either the top, or the side of the chassis, to enable vertical or horizontal orientation of the jaws.

The TS2 unit features and specifications are:

- Hardox® 450 plate throughout for strength, wear resistance and light weight

- CNC machined Hardox® blade

- Attachment Weight: under 160kgs

- Carrier Excavator Weight: 2,000 to 4,900 kgs

- Cut diameter: up to 200mm hardwood

- Side or top mount bracket options as standard.

British Made, in our Staffordshire works.

Manufacture time 2 to 4 weeks.

for PEL-JOB EB22.4Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

If you're looking to efficiently and effectively clear trees and vegetation, with minimal manual labour, our state-of-the-art tree shears are exactly what you need. The power and efficiency of our tree shears and take your projects to new heights.

Tree Shears:

The Tree Shear Range:

8 Bolt Pivot Pins

All our Tree Shears feature our ultra-secure, 8-bolt, end-cap retained pins, which not only vastly reduce the risk of a pin coming lose in operation, but also act under tension as a structural member of the shear assembly.

The pivot pins on a tree shear are under a lot of load. They're also hidden from the operator's view much of the time, obscured by the hitch, excavator arm and often branches too. If you're relying on a basic

castellated nut, held by nothing more than a split pin or cotter pin, is that enough and how does it work structurally?